SPLITTER TYPE

PHOTO GALLERY

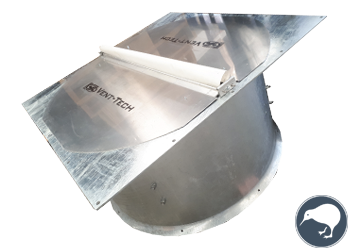

Splitter Type Silencers

- Choice of drilled RSA or cleat type flanges

- Higher attenuation patented bend type

- Galvanised steel construction

- Mineral fibre splitter infill

- Erosion resistant to airflow

- Optional moisture resistant lining

- Low resistance to airflow

- Various material and finish available

- Fully tested high temperature models available

- Fully metric range

Casing: Lock formed pre-galvanised steel sheet. Flanges rolled steel angle hot dip galvanised for duct connection or, formed flanges of pre-galvanised steel strip for cleat fixing (Code WSY). Alternatively spigot ends can be provided, please enquire. All welded cases are available for duct pressures between 1000 and 3000 Pa (Variant code P).

Splitters: Frames are formed from pregalvanised sheet steel. Absorbent material is resin bonded mineral fibre, in slab form with erosion resistant facing. A melinex lining (Variant Code M) can be supplied for critically clean applications, such as hospitals to ensure no fibre migration. The lining may also be used in moisture or grease laden conditions, such as kitchen extract systems where the material is used to stop the ingress of grease etc. into the acoustic media. The use of the lining also allows the silencer to be low pressure steamcleaned. Some reduction in attenuation due to the lining will be experienced. Splitters are normally mounted vertically in casing. For horizontal splitters please enquire.

Performances: Data is derived from tests to BS4718 1971. Measurements of a noise source are made with and without the silencer in position. The difference between the recorded levels is the static (without airflow) attenuation or insertion loss of the silencer.

Size Range: Standard height (inside duct): 300- 1500mm in 150mm increments. Standard lengths: 600-2400mm in 300mm increments. Larger silencers are supplied in sections to be fixed together on site. Silencers can be manufactured to suit any applications, please discuss with the acoustic department.

Fume Handling: For mildly corrosive atmosphere epoxy paint is available (Variant Code K). Where this finish is not sufficiently corrosion resistant many sizes can be supplied constructed in PVC of polypropylene. Please enquire giving details of the application.

Temperate Range: WS, WSY, WBS -40° to + 200°C Melinex Lining (M) -40° to + 80°C High Temperature (T)-40° to + 200°C PVC -40° max. Polypropylene -60°

Low Pressure Loss: Inlet and outlet fairings (Variant Code L) fitted to the splitters reduce pressure losses by 25%. The silencer Casing is increased by 300mm to accommodate the fairings.

90° Bend Type Silencers: Type WBS is a modified splitter silencer with integral air turning vanes to keep pressure loss to a minimum. Additional attenuation can be obtained (see table B) together with compactness in plant room layout.

- HOME

- ABOUT US

-

FANS

-

SILENCERS

- SPEED CONTROLLERS

-

GALLERY

- VICTORIA PARK TUNNEL

- OTIRA TUNNEL

- BELT DRIVE FAN

- Various Fans

- AHU built with 30kw Motor

- Fan Louvre Box

- Air Handling Unit with filters

- 1250dia Bifurcated Fan

- UDC FAN

- AXIAL FAN

- Vertical Discharge Fan

- SMOKE SPILL FAN

- PSCR UNIT WITH FILTER

- Axial fan for cold storage

- AX-3 Mixed flow Fan

- AX5 – Inline Centrifugal Fan

- AX5 Supply air fan louver box

- AX5-4543 split case

- DVCG - vertical discharge roof fan

- AX5 1200x1200mm FAN

- Air Handling Unit with filters

- SEAT FAN

- CONTACT US